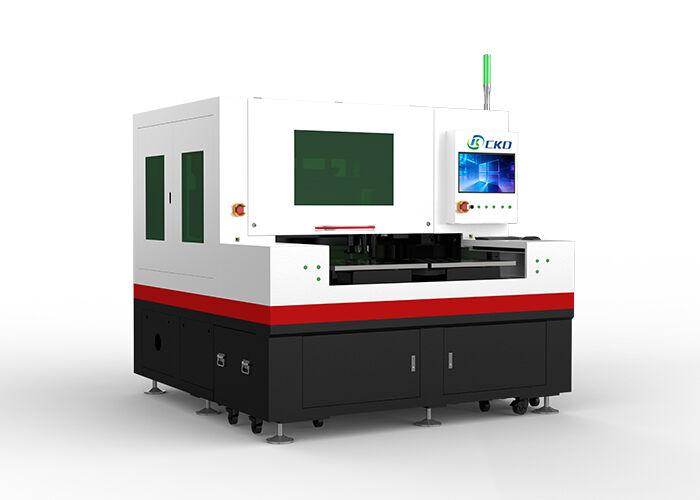

Laser Glass Cutting Machine built to support automated glass cutting processes with integrated control systems and software To Chipping ≤5μm

-

Soğutma SistemiSu Soğutma

-

AvantajlarıDüzensiz şekil yüksek hızlı kesme yüksek kesme kalitesi, konik, çapak yok, küçük yontma yüksek verim

-

Kontrol sistemiCNC denetleyici

-

Bakım GereksinimleriHer 200 Saatte Bir Optik Hizalama ve Her 1000 Saatte Bir Soğutma Sıvısının Değiştirilmesini Önerin.

-

lazer gücü30/50/60/75/80/90W

-

Otomasyon Sistemleriyle UyumlulukRobot Arayüzleri ve Otomatik Yükleme/Boşaltma Sistemleri Dahil Büyük Otomasyon Sistemleriyle Entegra

-

MalzemeBardak

-

Kesme kalınlığı0,03~25 mm

-

Kesim TeknolojisiLazer

-

Makine ağırlığı500kg - 2000kg

-

Grafik biçimiPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

Desteklenen dosya formatlarıAI, PLT, DXF, BMP, Dst, Dwg, DXP

-

Makine verimliliği0-500 mm/sn

-

Kesme doğruluğu±0,01 mm

-

Kesme Genişliği0,03-25 mm

-

YazılımCypcut

-

Kesme Hızı2000 mm/dak'ya kadar

-

Lineer Kılavuz MarkasıTPI

-

Sürüş SistemiStep Motor

-

Güç Tüketimi≤12KW

-

Hız0-500 mm/sn

-

yontma≤5μm

-

Lazer80W

-

NaneCam Lazer Kesim Makinesi

-

Güvenlik KorumasıYüksek Güvenlik

-

Çalışma MasasıPetek/alüminyum bıçağı

-

Kontrol yazılımıCypcut

-

Makine AğırlığıYaklaşık 150 kg

-

Ürün adıLazer Cam Kesim Makinası

-

Ürün TipiCam Kesme Makinası

-

Kesme YöntemiLazer Kesim

-

Kalınlık0,03-25 mm

-

Kesinlik±0,01 mm

-

Dalga boyu kapsama alanı1064nm

-

Kesme boyutu40*50cm*2

-

Desteklenen MalzemelerCam, temperli cam, lamine cam

-

Kesme kalınlığı0,5 mm - 20 mm

-

Doğrusal Hız1000 mm/sn'ye kadar

-

Hızı Kesmek0-500 mm/sn

-

Çalışma Tezgahı Boyutu1300mm x 2500mm

-

Destek Dosyası BiçimiPLT, DXF, BMP, AI, DST, DWG vb.

-

Güvenlik ÖzellikleriKoruyucu Muhafaza ve Acil Durdurma

-

Çalışma Frekansı50Hz/60Hz

-

Malzeme UyumluluğuBardak

-

Minimum Kesme Çapağı≤5μm

-

model numarası1064nm

-

Soğutma moduSu Soğutma

-

Servis ömrüUzun ömür

-

önemli satış noktalarıUltra hızlı pasea

-

Menşe yeriÇin

-

Marka adıCKD

-

SertifikaISO CE

-

Model numarasıCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-

-

Min sipariş miktarı1

-

FiyatNegotiated

-

Ambalaj bilgileriAhşap vakum paketleme

-

Teslim süresi25-45 Gün

-

Ödeme koşullarıL/C, T/T

-

Yetenek teminiAyda 60 set

Laser Glass Cutting Machine built to support automated glass cutting processes with integrated control systems and software To Chipping ≤5μm

Product Description:

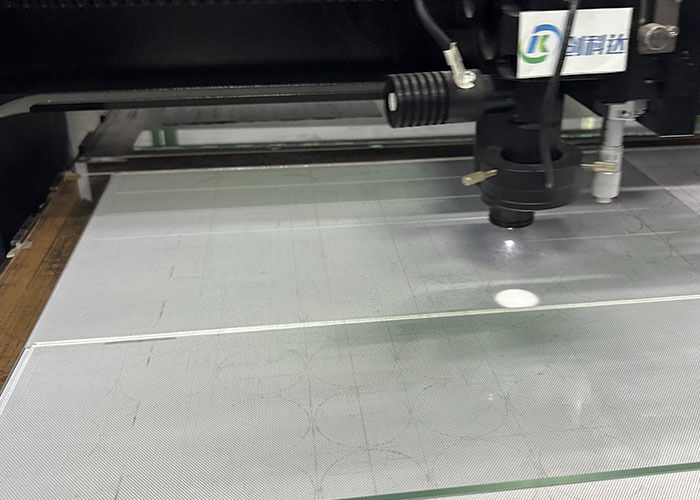

This device is an apparatus for efficient cutting of glass by high-energy laser, where the cutting is for profile machining, and CO₂ laser-assisted cracking used to achieve the cutting and cracking of glass.

Laser non-contact precision cutting, equipped with an automatic positioning system, achieves faster and more accurate identification and cutting; Significantly improve production efficiency, with neat and delicate cutting edges, high precision, no broken edges, and no burrs.

![]()

![]()

![]()

Technical Parameters:

| Splitting Laser Source | RFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling |

| Weight | 3500kg |

| Cutting Precision | ±0.01mm |

| Splitting Laser Source Cooling Method | Water Cooling |

| Material | Glass |

| Positioning Accuracy | ±2μm |

| Environmental Conditions | Works Best In Temperatures Between 15°C And 30°C, With 20%-80% Relative Humidity, Suitable For Cleanrooms Or Industrial Environments |

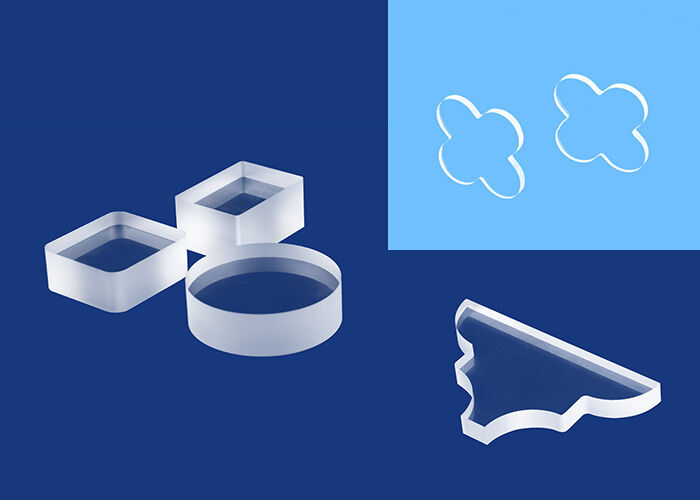

| Applicable Materials | Ultra Clear Glass, Plain White Glass, High Borosilicate Glass, Quartz Glass, Optical Glass, Cover Glass, Camera Glass Cover, Phone Glass Cover, Car Glass, LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, Etc. |

| Linear Speed | Up To 1000mm/s |

| Splitting Laser Source Laser Type | RFC02 (Radio Frequency CO2) |

Applications:

Can process "ultra-clear glass, regular white glass, high boron silicate glass, quartz stone glass", etc., mobile phone cover, car glass cover, camera glass cover, etc., mobile phone sapphire cover, camera sapphire cover, sapphire light strip, K9 glass, filter film cutting, reflector cutting, etc. Optical glass.

![]()

![]()

Introduction to the company:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. was established in 2010. lt is a Ultrafast laser equipment manufacturer and automation new intelligent manufacturing solution provider that integrates R&D, production, sales, and service. After more than ten years of deep cultivation and accumulation, the company has accumulated more than 70 patents, passed CE certification,1S09001 quality management system certification, and Intellectual Property Management System Certification. lt is a national high-tech enterprise and a Shenzhen Professional, Refined, Special, and Innovation Enterprise.

The company has a sheet metal workshop, machining workshop, assembly workshop, and process development and debugging workshop, covering R&D, Production, Testing, Sale & after service.

Up to now, the company has strong R&D team that has been engaged in laser structural design and laser application technology for many years. With a strong R&D ability and core software technology, the company has achieved innovation and break-through in product technology in fields such as ultra fast laser cutting, laser drilling, TFT-LCD screen laser repair, semiconductor plastic sealing and debonding, diamond grinding, laser welding, and laser marking. Especially in the processing of hard and brittle materials such as glass and ceramics, TFT-LCD repair, semiconductor plastic sealing and debonding, as well as diamond grinding and other automated new intelligent manufacturing, we provide cus- tomers with low-cost, high-quality, and high-efficiency solutions,making contributions to customer with value-added,innovation,and development.

![]()

![]()

![]()

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged to ensure safe delivery and protection during transit. The machine is first wrapped with anti-static foam and protective film to prevent scratches and dust accumulation. It is then securely placed in a sturdy wooden crate with internal cushioning to absorb shocks and vibrations. All fragile components are individually boxed and labeled. The packaging is designed to withstand long-distance shipping and handling, ensuring the product arrives in perfect condition.

Shipping:

We offer reliable shipping options for the Laser Glass Cutting Machine worldwide. The product can be shipped via sea freight, air freight, or express courier depending on the customer’s preference and destination. Before shipping, the machine undergoes thorough inspection and testing to guarantee quality standards. Tracking information will be provided once the shipment is dispatched. We also assist with customs clearance and provide all necessary documentation to ensure a smooth delivery process.

![]()